What Is Earthing? Why Earthing Is Important for Electrical Safety

If you’ve ever wondered how electricity safely flows in your home or office without zapping you, the answer lies in earthing. Before diving deep, it’s essential to find a trusted solution for installation. An Earth PIT Chamber manufacturer in India, like Aeron Industries, can provide reliable equipment to ensure your electrical systems are safe, compliant, and effective. Proper earthing is the backbone of any electrical safety plan, whether in residential buildings, commercial setups, or industrial plants.

Electrical safety isn’t just a technical necessity; it’s essential for everyday life. And at the heart of electrical safety? The earthing system.

In this blog, we’ll cover:

- What is Earthing

- Why Earthing is crucial for electrical safety

- What is Earthing in electrical installations

- Types of Earthing and Electrical Earthing

- Components and how earthing works

- Practical applications and safety best practices

- Wrapping up with key takeaways

Let’s electrify your understanding, safely!

1. What Is Earthing in Electricity?

In simplest terms, earthing (also known as a grounding system) is the practice of connecting electrical systems to the earth using a low‑resistance conductive path.

When electrical installations are properly earthed:

- Leakage currents take the safest path, into the earth

- People stay protected

- The equipment avoids damage

- Fire hazards have reduced significantly

In technical circles, earthing means the connection between an electrical installation and the earth that provides a safe discharge path for fault current.

Humans didn’t evolve with lightning rods, so yes, sometimes we do need technology to help Mother Nature!

Why Is Earthing Important for Electrical Safety?

Let’s break it down into real‑world logic.

Electricity itself isn’t evil, but unplanned or stray currents are. Imagine stepping on a banana peel in the dark, awkward and dangerous. Earthing prevents electrical “banana peels.” Here’s how:

Protects Against Electric Shock

When insulation fails or wires short, a dangerous voltage can appear on metal parts. Proper earthing channels that divert fault current into the ground rather than through a human body.

Limits Fire Hazards

Fault currents generate heat. If stray electrical current sneaks through flammable materials, fire can ignite. Earthing offers a controlled escape route.

Stabilises Voltage Levels

The earth acts as a voltage reference point. This helps electrical systems operate at predictable and safe voltages, especially in complex installations.

Enables Sensitive Protective Devices to Work

Circuit breakers and other devices rely on fault currents returning to earth so they can trip quickly. Without earthing, those devices may not even know a fault exists.

Electrical Earthing vs. Grounding: A Quick Clarification

You might have seen earthing and grounding used interchangeably. In many contexts, they mean the same thing. But there’s a subtle distinction:

- Earthing is connecting the non-current-carrying parts of equipment to earth.

- Grounding often refers to tying electrical circuits or systems to a reference point (sometimes not directly to earth).

For most individuals, both terms serve the same safety function. Professionals might pick one term based on standards, but both protect people and equipment.

What Is Earthing in Electrical Installation?

When electricians perform electrical installation, whether in homes, commercial buildings, or factories, they make sure every non‑live metal part connects to the earth.

Here’s how a typical earthing connection works:

- The electrical appliance frame connects to

- The earthing conductor, which leads to

- Earthing electrode buried deep in soil/earth

This network ensures fault energy doesn’t sneak through you when you touch that faulty fridge!

Types of Earthing and Earthing Systems

There are several types of earthing used in electrical installations. Each suits specific installation needs and soil conditions.

Plate Earthing

A metal plate (usually copper or galvanized iron) is buried vertically. It provides low resistance and is common in residential setups.

Pipe Earthing

A perforated galvanized steel or copper pipe is driven deep into the earth. Best for soils with high resistance.

Rod Earthing

Here, a rod (commonly copper or galvanized iron) is hammered vertically into the ground. Often seen in modern installations for its simplicity and effectiveness.

Strip or Wire Earthing

In this method, a long conductive strip is buried horizontally in the soil. It’s useful when a wide surface area improves conductivity.

Electrical Earthing Types (Based on Purpose)

Electrical earthing has two main functional categories:

Neutral Earthing

The neutral point of a system (like in transformers or generators) is directly tied to earth.

Equipment Earthing

This connects the non-current-carrying metal parts of machines or appliances to earth.

Both types work together to ensure safety and system integrity.

Main Components of an Earthing System

A typical earthing or grounding system includes:

- Earthing Electrode – steel or copper rod/plate buried underground

- Earthing Conductors – wires that connect equipment to the grounding point

- Bonding Connections – ensure all metallic parts stay at the same potential

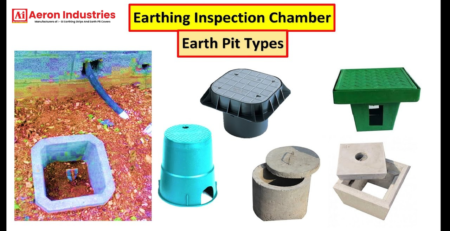

- Earth Pit Covers – for easy inspection and safety

All of these contribute to a reliable earthing system that protects people and equipment around the clock.

How Earthing Works: A Practical Example

Let’s imagine:

You plug in a toaster. A fault causes the heating coil to touch the toaster’s metal case. Without earthing:

Touching the toaster could send current through your body, very dangerous.

With earthing:

Current flows safely into the earth through the earthing system instead of through you.

That’s electrical safety in action, and that’s why proper grounding is never optional.

Earthing and Electrical Safety Standards

Across the globe, electrical codes and safety standards make earthing mandatory. These standards:

- Define acceptable resistance values

- Specify how deep the electrodes must be placed

- Describe conductor sizes

- Outline periodic testing procedures

In many countries, regulations enforce earthing in residential, commercial, and industrial installations to ensure safe electrical environments.

Maintenance of Earthing System, You Can’t “Install and Forget.”

Even the best earthing systems need to be tested periodically. Why?

- Soil conditions change

- Corrosion slowly increases resistance

- Connections loosen over time

Regular testing and maintenance ensure the earthing resistance stays low, and the system remains effective. Checking once a year helps avoid future hazards.

Conclusion: Why Earthing Matters

From homes to skyscrapers, power installations to smart devices, earthing is a silent hero. It’s not glamorous, but it’s necessary. Without it, electrical faults could lead to harm instead of harmlessly dissipating into the earth. By understanding what earthing is, why earthing is important, and how earthing in electrical installations works, you make smarter design and safety decisions. Whether you’re an electrician, a homeowner, or a safety inspector, this knowledge keeps you electric shock‑free!

Leave a Reply